Latest news

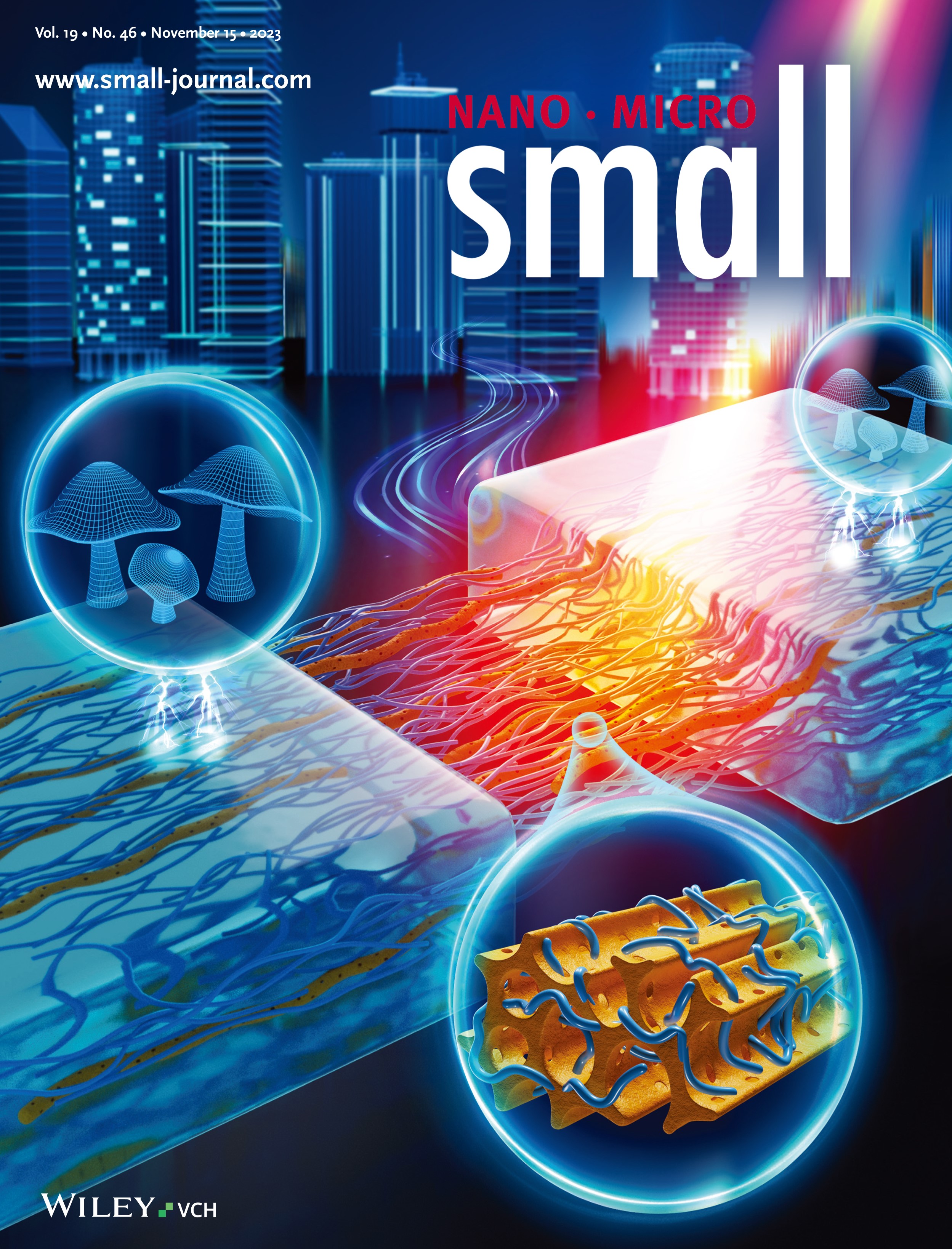

Recently, the wood protection and modification research team from the College of Material Science and Technology of BFU has made new progress in wood insulation materials. The research result "Mycelium Composite with Hierarchical Porous Structure for Thermal Management" was published in Small (IF=13.3), and was selected for a magazine cover story.

Lightweight thermal insulation materials with excellent mechanical properties are essential for the transportation and storage of temperature-sensitive items and electronic/thermal equipment and for ensuring the comfort of building interiors. Popular commercial insulation materials include petroleum-based lightweight foams such as expanded polystyrene (EPS) and expanded polyethylene (EPE). Plastics such as these have one of the largest carbon footprints, accounting for 15% of worldwide carbon emissions. Therefore, creating highly sustainable and energy-efficient materials from naturally biodegradable polymers can minimize the reliance on fossil fuels and curb greenhouse gas emissions from human activities. Wood is a highly sustainable material due to its low carbon footprint, energy efficiency, renewability, and plentiful availability. Its layered cell structure and directed fiber arrangement allow it to be lightweight and have anisotropic mechanical strength. The evolution of wood into thermal insulation materials such as transparent wood and wood aerogels has been investigated. To minimize the solid contribution and enhance the tortuosity of the pore structure, all lignin and a portion of hemicelluloses were removed from the wood by chemical treatment, which reduced the conduction of solids and gases within the wood. However, strategies for lignin removal by chemical pretreatment have high energy consumption, complicated manufacturing procedures, and low economic efficiency.

Here, the research team developed a hierarchical porous structural mycelium composite by using multiple T. versicolor mycelium networks to bind loosely-distributed sawdust. Forestry by-products were utilized in this approach, minimizing energy consumption during production and meeting the expectations for an inexpensive and highly sustainable product. This approach was deemed cost-effective, despite the long manufacturing period, as demonstrated by large-scale production and broad applicability, as well as reusability and repairability. The thermal, acoustic, and cushioning properties of the composite were comparable to or even better than those of other popular lightweight foams currently on the market. Furthermore, it demonstrated great hydrophobicity, repairability, recyclability, and modularity. These hierarchical porous structural mycelium composites with a low carbon footprint are strong contenders for lightweight foams and are expected to be adopted for insulation in the building and transportation packaging industries. It is expected that the hierarchical porous structural composite with excellent thermal and mechanical properties can make a significant impact on the future development of highly sustainable alternatives to lightweight plastic foams.

The first author of the research paper is Zhang Mingchang, a doctoral student in the College of Material Science and Technology, and the corresponding author is Professor Cao Jinzhen. Beijing Forestry University is the signature unit of the first author. This work was financially supported by the Fundamental Research Funds for the Central Universities of China (2019JQ03013).

Paper: https://doi.org/10.1002/smll.202302827